A three-year, EU-funded research project, dubbed DIGESPO, an acronym for ‘Distributed CHP Generation from Small Size Concentrated Solar Power’, has just completed the installation of a pilot micro Combined Heat and Power (m-CHP) plant, based on innovative Concentrated Solar Power (CSP) and Stirling engine technology, in Malta.

The solar power plant is designed and built to simultaneously provide electrical power and heating for single and multiple domestic dwellings or other small buildings.

The Bruno Kessler Foundation in Trento, Italy, is the lead coordinator of this research effort, together with other partners (industrial, research and universities) from Italy, Germany, Sweden, Malta and the United Kingdom.

The project consortium is currently testing various improvements to the current state of art, which have been developed within the project. The DIGESPO target is to improve the efficiency of similar plants from circa 40 per cent to 65 per cent of incident solar radiation, and will provide from one to two kilowatts of electrical energy and seven to eight kilowatts of thermal power.

This ambitious target is being achieved via a number of subtle innovations and improvements, mostly focused at researching and improving the composite coatings for solar absorption, the heat transfer medium, the introduction of flexible reflective glass technology, improvements in evacuated glass tube technology, and the implementation of advanced Stirling heat engines, capable of converting heat energy into electrical energy.

The project is being hosted at ArrowPharm (Malta) Ltd., which has allocated roof space at their state-of-the-art factory in ?al Far, as part of the company’s drive to encourage the use of renewable energy and energy efficiency. ArrowPharm is part of the Watson group, a leading global pharmaceutical company engaged in the development, manufacturing, marketing, sale and distribution of generic, brand and biologic pharmaceutical products.

Sergio Vella, General Manager at ArrowPharm, reiterated the organisation’s commitment to this pilot project. This initiative enjoys the company’s positive support, since it contributes towards the facility’s industrial heat and power requirements, while providing useful data related to the exploitation of solar energy and fitting in perfectly with ArrowPharm’s corporate social responsibility philosophy.

The DIGESPO demonstration project is essentially prototyping new technologies and all the necessary effort is being made to patent numerous technological improvements and develop them on an industrial scale to arrive at market-ready systems.

Projects in Motion, an SME enterprise with a strong focus on research and development, is responsible for the local system integration and installation. Besides contributing technically, Projects in Motion is also gathering a substantial amount of data related to direct and indirect solar radiation on the Maltese islands.

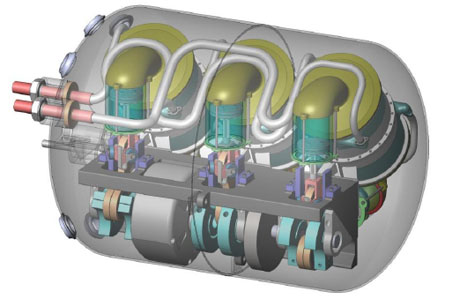

The stirling engine power conversion device operates by extracting work from a temperature differential between the hot heat exchangers in the engine and the cold heat exchangers in the engine. This temperature differential is effected by circulating a heated fluid (water, steam, heat transfer fluid, or other) into and out of the hot fluid ports of the engine, while simultaneously circulating a cooler fluid (water, glycol, or other) into and out of the cold fluid ports of the engine. The pumps to create this liquid circulation are external to the engine and provided by the system integrator. The other connections on the P3 engine are electrical sensor leads for monitoring internal temperatures and pressures, and the three electrical leads connected to the internal motor/generator integrated into the driveline of the engine. This motor/generator is used to spin up the engine on start-up, and then to produce electrical energy when the engine is running on the temperature differential. The P3 SolarHeart Engine is expected to produce a 3kWe maximum output at 300°C hot fluid temperatures and 20°C cold fluid temperatures.