- Awarded additional $20.3 million from the U.S. Department of Energy (DOE) to build and test a prototype of an ultra-efficient, lightweight superconducting generator

- Applying 40+ years of IP and application experience scaling superconducting magnet technology for GE’s Magnetic Resonance Imaging (MRI) business to increase wind energy output

- Leveraging well-established supply chain for MRI to produce lower cost wind power

- Use of superconducting magnets would eliminate the need for rare earth materials in future generator designs

Could the high field magnets used in MRI scanners that help doctors see and diagnose disease inside the human body unlock the key to generating more wind energy? A multi-disciplinary team of GE engineers at GE’s Research Lab in Niskayuna, NY has been awarded $20.3 million in follow-on funding by the DOE’s Wind Energy Technologies Office to accelerate the design and testing of a new superconducting wind generator.

The team at GE Research, both pioneers and leaders in scaling superconducting magnet technologies for Magnetic Resonance Imaging (MRI) scanners in healthcare, are applying decades of experience to develop a more powerful generator for offshore wind turbines. The additional funding from the DOE is a testament on the team’s progress to date and on the potential of this new type of generator.

“The industries and applications are vastly different, but the technical challenges and goals are very similar,” said David Torrey, a Senior Principal Engineer and Project Leader on the Superconducting generator project. “With MRI, we have worked over many decades to increase the magnetic field of the superconducting magnets to deliver better image quality. In wind, we’re seeking to strengthen the magnetic field of the magnet to make generators that deliver more wind power with higher efficiency. And with both applications, the goal is to enable these improvements while minimizing their size and weight.”

“Can we pack more power in the same space with less weight?” Torrey asked. “We’ve done this successfully with MRI systems time and time again. We think we can do it with wind power as well.”

In addition to increasing power while minimizing the size and weight of the generator design, Torrey noted that the use of superconducting magnets also would eliminate the need for rare earth materials, essential ingredients in the permanent magnets currently being used in offshore wind turbines. Today’s generators typically use about a ton of permanent magnets for each megawatt of rating.

Torrey explained that working with scientists and engineers on the GE Research campus in Niskayuna provides GE’s businesses with both access to the Center’s broad range of technical capabilities and experience scaling technology across our multiple industries. The Research Center has a building on campus dedicated to MRI research and developments that his team is now connected with to support this new wind program. “Despite the vast differences between an MRI scanner and offshore wind turbine, the size and scale up required with the magnetic fields to support the offshore wind generator are not that different from what the team has experienced with MRI scanners,” Torrey said.

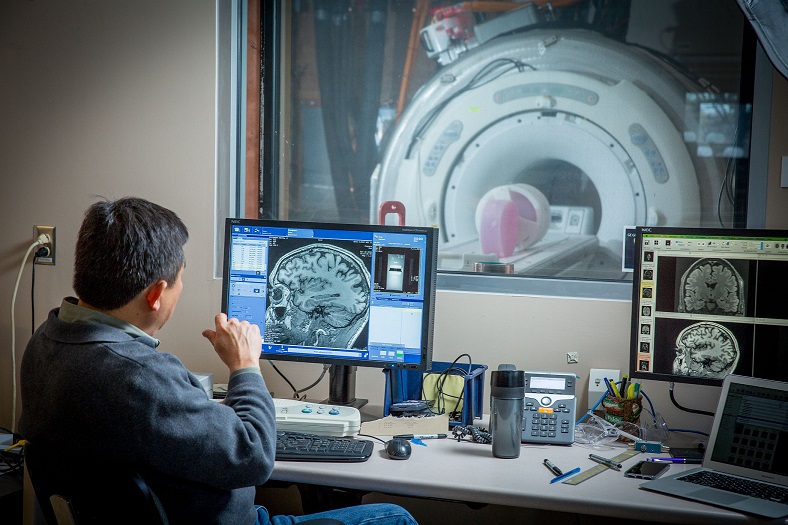

Caption: A glimpse inside GE Research’s MRI Lab at our research campus in Niskayuna, NY. GE researchers are applying decades of experience scaling superconducting magnet technologies for MRI scanners to develop a new superconducting wind generator.

Over many decades, GE Research’s MRI team has pioneered important advancements in superconducting magnets to strengthen their magnetic fields. The first MRI systems introduced were on the order of 1.5T, but over time have increased in field strength to 3T while maintaining a comparable size and weight. GE researchers are currently developing a 7T Head-Only MRI system that would more than double the magnetic field strength, while containing the size and weight of the system.

The challenge of scaling up wind power is not dissimilar. With the generator, the key is delivering more power without increasing the size and weight of the generator itself. The team believes it can apply both the technical expertise and experience scaling MRI technology on the healthcare side to develop a superconducting generator that delivers more power within the same footprint to achieve higher annual energy production (AEP) with reduced weight. This drives down the levelized cost of energy, a key challenge in offshore wind.