Noor Energy 1 partners are mitigating logistics, cost and labor shortage challenges to keep the world’s largest Concentrated Solar Power project on schedule.

On March 27, Shanghai Electric hoisted into place a 200-ton thermal oil overflow tank at the 950 MW Noor Energy 1 CSP-PV project in Dubai.

Measuring over 52 meters in length, the delivery and installation of the tank represents the first major project milestone at Noor Energy 1 since coronavirus restrictions slowed down site activity.

Developed by Saudi Arabia’s ACWA Power, the $4.4 billion Noor Energy 1 project will be the world’s largest CSP plant and includes a 100 MW CSP tower plant, three 200 MW parabolic trough CSP systems, 250 MW of PV capacity and 15 hours of molten salt CSP storage capacity. Shanghai Electric is the lead construction company while the main components are being supplied by European and US firms, some using Chinese facilities.

Coronavirus lockdowns have disrupted supply chains and severely restricted national and international travel.

Despite ongoing restrictions in many countries, Shanghai Electric believes it can meet its first commercial operation deadline of August 2021, when the first 200 MW power trough section is due online, the company said last month.

Noor Energy 1 construction partners have installed the first of 27 giant overflow tanks for the parabolic trough sections. (Image credit: Shanghai Electric)

Shanghai Electric has resumed construction after hiring over 900 additional local workers and using videoconferencing to streamline communications, it said.

Noor Energy 1 is being built in phases. The CSP tower plant is due online by November 2021, followed by the second and third parabolic trough sections by April 2022 and December 2022, respectively.

Construction advanced ahead of schedule last year and suppliers are managing cost and logistics challenges to ensure the project can meet its commissioning deadlines, project partners told New Energy Update.

Thus far, supply chain disruption has been limited to “minor delays in non-critical supplies,” Abengoa, supplier of the parabolic trough section, said.

There has been no major impact «beyond specific health protocol at site” and the commercial operation dates remain in place, the Spanish company said.

Delivery challenge

The Dubai Electricity Water Authority (DEWA) awarded the Noor Energy 1 project in 2017 at a record-low tariff of $73/MWh. DEWA acquired a 50% stake in the project and is the power offtaker under a 35-year power purchase agreement (PPA).

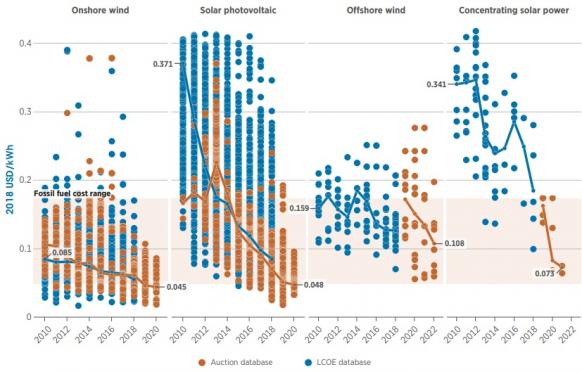

Global levelized costs for solar, wind in 2010-2022

(Click image to enlarge)

Source: IRENA’s ‘Renewable power generation costs in 2018’ report (May 2019).

The scale of the Noor Energy 1 project represents a huge logistics and construction challenge. Prior to the coronavirus outbreak, the schedule was already demanding, with construction of the entire project expected to take less than four years.

The parabolic trough units alone require the delivery of 8 million square meters of mirrors transported in 180 containers per month, as well as 500 trucks of steel per month, according to Abengoa. Abengoa is supplying the parabolic trough systems under a $650-million deal with Shanghai Electric and is also the main solar field subcontractor.

The overflow tank is the first of 27 to be connected to the 600 MW parabolic trough section of the plant.

The giant vessel was transported by sea to the port of Jebel Ali, UAE and then transported 90 km by road to the site. The project partners worked with local authorities and police forces to obtain transportation permits and coordinate the transit, using telephone and video communications where necessary, Shanghai Electric said.

Hoisting and safety procedures were meticulously planned in advance, the company said.

Absorbing the impact

By May 2019, early progress had accelerated construction of Noor Energy 1 project to 7% ahead of schedule, Dubai Electricity and Water Authority (DEWA), co-owner of the project and contracted power offtaker, said last year.

Supply chain disruptions from COVID-19 have been confined to non-critical components and these can be absorbed by contingencies built into the project schedule, Abengoa told New Energy Update.

For Abengoa, no acceleration in construction is required to meet commissioning deadlines, the company said.

Travel and transport restrictions have impacted some logistics costs but these are being managed, Jayesh De Silva, Business Development Manager at US group BrightSource Energy, told New Energy Update. BrightSource is technology supplier and co-constructor of the CSP tower and is supplying design, engineering services and solar field controls.

“We have had some challenges and cost repercussions with procurement, shipping and logistics as countries that we import these items from close their borders and/or fewer flights for air freight are available,” De Silva said.

There was limited impact on the supply of engineering expertise, solar field controls and conceptual design services, he noted.

The restart of manufacturing operations in China will also ease supply concerns.

On March 25, Denmark’s Aalborg CSP said its Chinese partner Shanghai Boiler Works had restarted production of 42 heat exchangers for the project. Aalborg CSP is supplying its header-and-coil steam generation technology for the parabolic trough section.

«With all employees wearing masks, the machines are up and running again and the work can continue under the safety measures implemented,» Aalborg CSP said.

Hiring local

To minimize the impact of travel restrictions, Shanghai Electric and construction partners launched a huge local recruitment drive for Noor Energy 1, the company said last month.

Since January, Shanghai Electric has worked with local partners to establish a specialist virus prevention and control team to protect staff while working on-site, it said.

In total, Noor Energy 1 is expected to create 6,000 new jobs in construction and operations. In January there were some 3,200 employees on site, according to Abengoa.

«We are likely to go ahead of the timetable in extending local talent pool as an outcome of the epidemic outbreak,» Zhao Hui, Noor Energy 1 Project Manager, said in a statement.

«People are the main force for resuming to normal work,” Hui said.

Ongoing risk

With a great deal of work yet to be completed at Noor Energy 1, the continuing impact of the coronavirus epidemic on global supply and travel remains a risk.

“The situation going forward is fluid and difficult to predict,” De Silva said.

ACWA Power fully expects its construction partners to fulfill contractual obligations and mitigate the impact of the COVID-19 pandemic «without compromising the health and safety of staff and the community,» Paddy Padmanathan, CEO of ACWA Power, told New Energy Update.

A good indicator of project progress will be the hoisting of the molten salt receiver on top of the 260 m tower, scheduled for completion in May.

By Kerry Chamberlain, newenergyupdate.com/csp-today